Steel Rolling Mill Plant – Abu Dhabi

CRHI have been appointed as detail design consultant the design build contract of the 600 million dollar extension to the existing Emirates Iron and Steel Factory in Mussafah, Abu Dhabi. The project is of a fast track turnkey nature working to tight schedules.

CRHI’s services include the design of all foundations for the steel structures, structural design of water treatment plants, reverse osmosis plants, machinery foundations, pump rooms and ancilliary buildings. The infrastructure works include structural design of pavements, coordination of below ground services and foul and surface water drainage design.

CRHI have also provided expert advice on ground improvement techniques, excavation and temporary works and provided detailed analysis of the most appropriate materials for the project, mix design for concrete, protective coatings for concrete and steelwork.

Working to the Clients exacting technical specification CRHI have successfully delivered this project on time with the required high standard.

National Recycling Park

National Projects Holding Co. commissioned CRHI to manage the design of a major Recycling Park which is to be located in the centre of the industrial area of Dubai Industrial City (DIC) receiving solid waste from a combined workforce and resident population of 150,000 people.

The Recycling Park is being implemented with the intention of providing facilities to recycle industrial, commercial and household waste generated within DIC such as plastic paper and organic waste.

CRHI is providing consultancy services associated with:

- Environmental Impact Assessment

- Traffic Impact Assessment, Design of Internal Roads and parking

- Building Design Services

- Landscaping

Hitech F.Z.E – Jebel Ali Free Zone

CRHI was appointed to carry out the design, value engineering, and site monitoring of a dust free environment lens factory in Jebel Ali Free Zone – Dubai. The client required that the whole design and construction be complete for client take over in a mere 6 months period.

The production unit of this factory was to be air tight with a particle size limited to 0.30 micron which required accurate supervision and installation of all production unit components. In order not to disrupt the calibration of the optical equipment the airconditioning system was carefully designed to minimise the velocity of air flow and yet keep the building in a pleasant working environment.

The building structural system was a reinforced concrete sway frame for the administration area, and structural steel portal frames spanning 26 m in the production area. These foundations were isolated footings on vibro-replacement ground improvement.

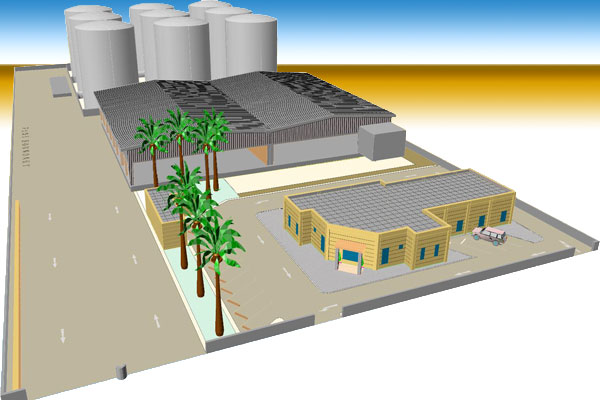

Central Workshop + Batching Plants – Jebel Ali

Al Nabodah Bin Hafeez General Contracting Company appointed CRHI to design and supervise an industrial compound of batching plants with related amenities.

The compound occupied a total land area of approximately 67,000 m² which was developed into a several baching plants for concrete, asphalt, wet mix and dry mix facilities, in addition to offices, warehouses, carpentry workshop, guard house with a weigh bridge, internal roads, parking, and a power house. The main buildings were mainly structural steel sway frames. The boundary wall was more than 1,000 m long.

Administration Offices & Oil Refuelling Facilities

CRHI were appointed by Solvochem Emirates to project manage the development of their regional headquarter offices and refuelling facilities in Jebel Ali Free Zone.

CRHI were selected for their wide experience in dealing with industrial projects in the United Arab Emirates and their commitment to quality and time. The project is on tight programme of six months from inception to delivery.

Unit III Umm Al Nar

CRHI were appointed by Al Nasr Irrigation and Contracting Company to detail design a compound housing pumping facilities for this design and build project at Unit 3 Umm Al Nar Water Supply Pipe Line in Abu Dhabi. The project entailed a very short period of 7 weeks to detail design, produce drawing and obtain approval to proceed with construction, which was successfully achieved. The main pumping house structure comprised a steel portal frame spanning 20m on a concrete underground raft with a minimum thickness of 600 mm, were as the switch gear building was a reinforced concrete sway frame on isolated pad foundations.